Asset Maintenance and Tracking in CMMS- How It Works, Features, and Benefits

Your business’s lifeline depends on those hardworking assets – equipment, machinery; you name it. Without them, chaos reigns! So why not embrace the magic of CMMS, the ultimate genie granting your asset management wishes?

Did you know that businesses worldwide are swearing by CMMS’s capabilities? Oh, it’s not just a trend – it’s a necessity!

Here’s the scoop: actual stats reveal that companies using CMMS witness a whopping 25% reduction in maintenance costs as per ReliabilityWeb. Imagine the savings! But it’s not just about the numbers; it’s about the transformation it brings to your business’s soul.

Say goodbye to the days of guessing when your equipment needs TLC. CMMS empowers you to track the pulse of your assets, knowing precisely when they need that extra care.

No more unexpected breakdowns or emergency repairs to ruin your day. It’s like having a personal assistant, ensuring your assets are always at their best, ready to tackle any challenge.

What is Asset Maintenance Management?

Asset maintenance management refers to tracking and managing the service and repair of an organization’s physical assets. These assets may include equipment, facilities, and other physical resources essential to the organization’s operation. Asset tracking is an essential aspect of the CMMS process.

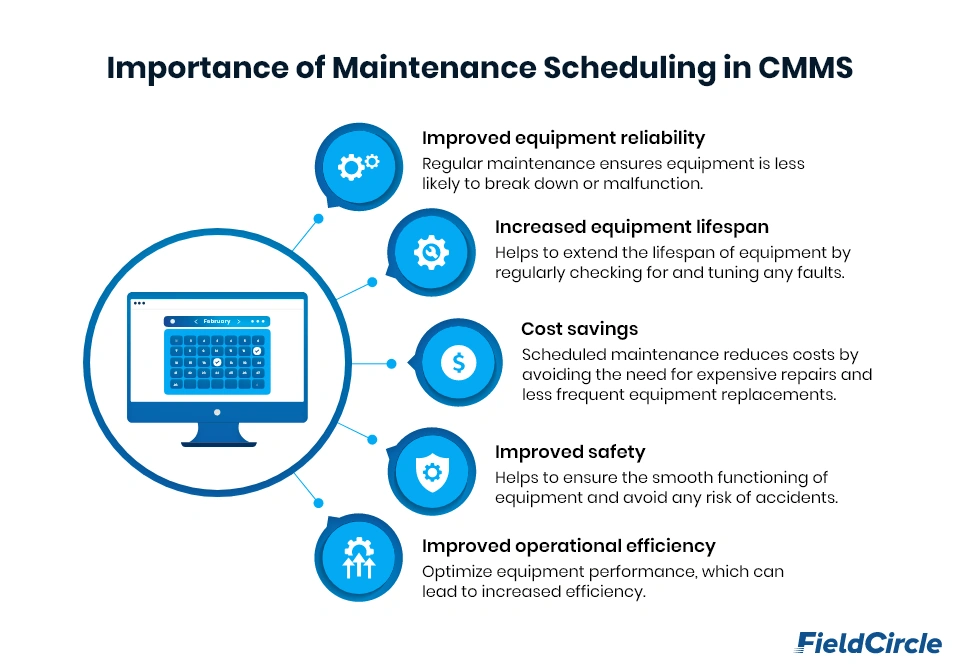

Using a CMMS for asset tracking allows an organization to maintain a comprehensive record of each asset, including its location, age, history, and current condition. This information can be used to optimize maintenance schedules, reduce downtime, and extend the lifespan of the assets.

It may involve using tools such as barcode scanners, tags, and tracking devices to collect and update asset data in the system automatically. This can help improve the accuracy and efficiency of asset tracking and make it easier for staff to access and update asset information.

The Functions of Asset Maintenance Management in CMMS

Some key functions of asset tracking in CMMS include:

- Asset registration: It typically begins with registering the asset in the system. This involves entering information about the asset, such as its make and model, serial number, location, and other relevant details.

- Repair tracking: A CMMS can be used to track the maintenance and repair history of each asset, including the type of work performed, the parts used, and the cost of the repair. This information can be used to optimize service schedules and extend the asset’s lifespan.

- Asset location tracking: It is used to track the location of each asset, making it easier to locate and dispatch assets when needed.

- Asset availability tracking: It can track each asset’s availability, including whether it is currently in use or available for service or repair.

- Performance tracking: Used to track the performance of each asset over time, including asset maintenance metrics such as downtime and repair frequency. This information can be used to identify trends and issues that may need to be addressed.

How Asset Tracking Works in CMMS

- The ability to accurately track the location of assets in real time.

- The ability to store and manage data related to each asset, including serial numbers, model numbers, and service histories.

- Alerts and notifications alert users when an asset is moved, accessed, or is due for maintenance.

- Reporting and analytics capabilities to help users understand how assets are being used and to identify trends and patterns.

- The ability to integrate with other interfaces, such as inventory management or enterprise resource planning (ERP) tools.

- Scalability to support the tracking of many assets across multiple locations.

- User-friendly interface to allow users to access and update asset information easily.

- Secure access controls to ensure that only authorized users can access and update asset information.

The Benefits of Asset Maintenance Management

There are several benefits to using a CMMS for asset tracking:

Improved asset visibility:

It provides a centralized digital record of all assets, making it easier to locate and track their usage, service history, and current condition.

Increased efficiency:

Automating asset tracking and service scheduling can streamline asset management processes and reduce the time and effort required to track and manage assets.

Reduced downtime:

Tracking assets’ service and repair history and proactively scheduling services can help reduce the risk of unplanned downtime due to equipment failure.

Improved asset utilization:

Tracking the usage and availability of assets can help organizations optimize their asset utilization and make more effective use of their resources.

Enhanced asset security:

It can help organizations track the location and usage of assets, reducing the risk of theft or unauthorized use.

Cost savings:

Optimizing service schedules and reducing downtime can help organizations to reduce service costs and extend the lifespan of their assets.

Preventive maintenance optimization:

A CMMS serves as a dedicated preventive maintenance tool. with which organizations can anticipate potential issues before they cause equipment failure, enabling proactive maintenance scheduling. This reduces emergency repairs, improves equipment reliability, and extends the lifecycle of assets.

Final Thoughts

Using a centralized solution for asset tracking can help organizations improve the efficiency and effectiveness of their asset management processes, reduce costs, and maximize the value of their assets. To achieve these benefits, it’s crucial to consider key CMMS software requirements—such as real-time asset status updates, maintenance scheduling, and reporting capabilities—that ensure the system supports informed decision-making. The assets’ up-to-date status provides important information for your business.

Asset tracking is very helpful in making operations more efficient. And always selecting the right service software application for your organization’s service needs is crucial. Learn more about how FieldCircle CMMS software is experienced in helping a wide range of industries to track and manage service activities effectively.