Mining Maintenance Software

Streamline your mining operations with FieldCircle’s cloud-based Mining Maintenance Software. Designed for the mining industry, our CMMS supports the maintenance of critical assets like haul trucks, crushers, conveyors, and drilling equipment. By enabling predictive maintenance, real-time asset tracking, and inspections, it prevents equipment failures and extends asset lifespan. Built to ensure compliance with MSHA and OSHA safety standards, it minimizes disruptions, promotes safety, and drives operational efficiency—helping mining companies achieve productivity and long-term success.

How Mining Maintenance Software Works?

Explore how the key features work without signing up for a trial or demo.

User Login

Users, typically maintenance managers or technicians, access the software by logging in with their credentials. Upon successful authentication, they gain access to the software’s dashboard and functionalities.

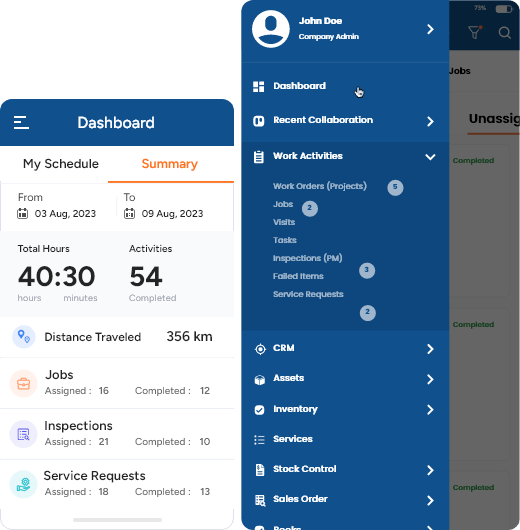

Dashboard Overview

Upon logging in, users are presented with a dashboard providing an overview of ongoing maintenance tasks, equipment statuses, upcoming schedules, and alerts. This gives users a snapshot of the maintenance activities across the mining site and acts as a centralized hub for users to access essential data and navigate through the software.

Submitting Maintenance Requests

Users, such as maintenance technicians or site managers, can submit maintenance requests through the software. They provide details about the issue, including equipment involved, description of the problem, and any other relevant information.

Assignment of Requests

Maintenance managers or supervisors receive the maintenance requests and assign them to appropriate technicians based on factors such as skill level, workload, and availability. Assignment allocation is typically done through the software’s interface.

Notification and Confirmation

Technicians receive notifications about the assigned maintenance tasks through our mining maintenance software. They confirm receipt of the task and review the details provided, ensuring they understand the scope of work and requirements.

Task Execution

Technicians execute the assigned maintenance tasks according to the instructions provided. They use the software to access relevant documentation, checklists, and procedures to perform maintenance effectively.

Completion and Documentation

After completing the maintenance tasks, technicians update the status of the tasks within the software. They provide details about the work performed, any parts replaced, and observations made during the maintenance process.

Quality Check and Approval

Maintenance supervisors or quality assurance personnel review the completed tasks within the software. They verify that the maintenance was performed according to standards, check for any discrepancies, and ensure that all necessary documentation is complete.

Feedback and Follow-Up

Users, including technicians and supervisors, may provide feedback within the software regarding the maintenance process. They can report any issues encountered, suggest improvements, or provide other comments for future reference.

Features of Our Mining Maintenance Software that Unlock Efficiency

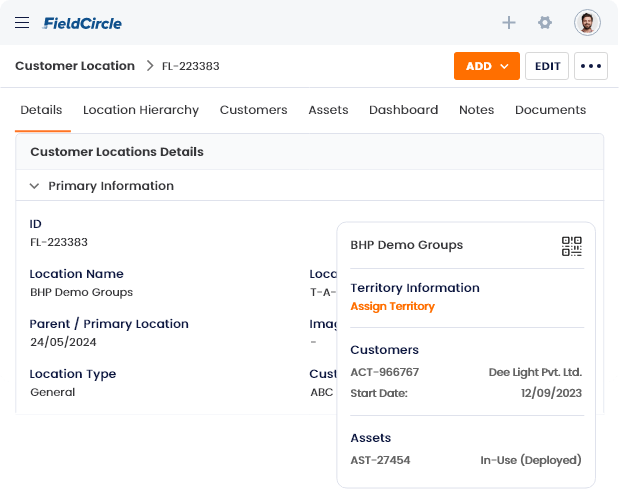

Customer & Location Management

FieldCircle’s Mining Maintenance Software provides a centralized database for storing detailed profiles of mining operations and client information. With automated geotagging capabilities, precise location management of mining assets and equipment across diverse locations becomes effortless. Intuitive interfaces allow quick access to customer histories, contract details, and site-specific maintenance requirements, enhancing operational efficiency. Integration with mapping software optimizes route planning for service visits and maintenance dispatches, providing real-time decision support and mobile accessibility for seamless operations management.

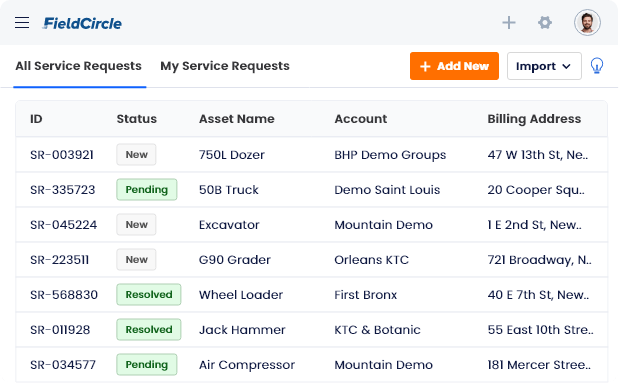

Service Request Management

Our mining maintenance software streamlines service request management with automated capture and categorization of service requests, whether initiated by clients or generated by predictive maintenance alerts. Real-time tracking of service requests enables quick allocation and dispatch based on urgency, location, and technician availability. User-friendly portals empower clients to submit and track their service requests easily, fostering transparent communication and efficient service delivery.

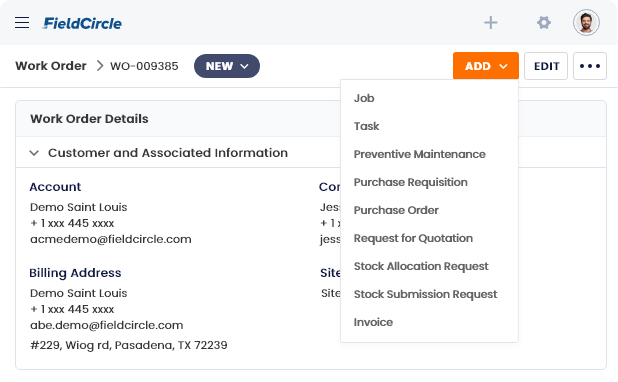

Work Order Management

The Work Order Management module of our mining maintenance software generates detailed work orders from service requests or preventive maintenance schedules, incorporating all necessary job details. Real-time update capabilities facilitate adjustments based on emergent needs or completion status. With mobile accessibility, technicians can view, update, and close work orders on the go, ensuring accurate and timely data capture. Our automated workflow ensures systematic processing, assignment, and tracking of work orders to completion, optimizing maintenance operations.

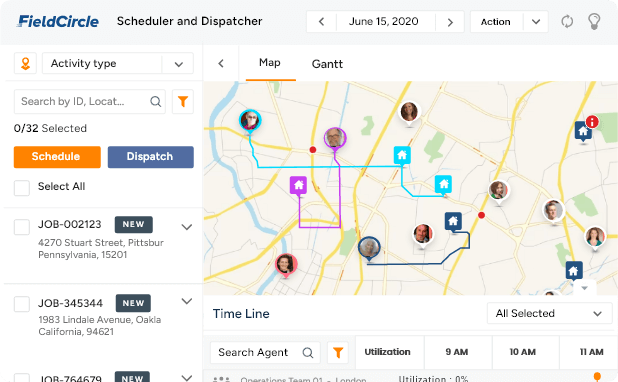

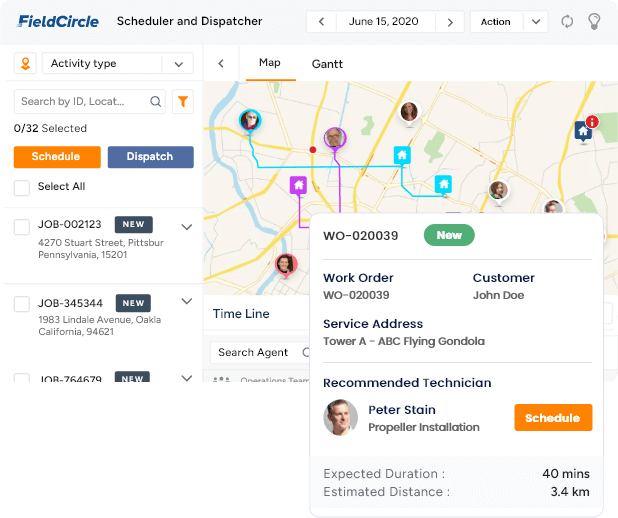

Scheduling & Dispatch

Dynamic scheduling tools automatically assign maintenance tasks to the right technicians based on skill set, location, and availability, ensuring efficient resource utilization. Real-time dispatch capabilities enable swift responses to urgent maintenance needs, minimizing downtime. Predictive scheduling leverages maintenance history, asset performance data, and predictive maintenance insights to optimize scheduling efficiency and enhance overall operational performance.

Technicians, Crew and Service Vendor Management

We offer comprehensive management of internal technicians, external service vendors, and crew teams within a unified system with our mining maintenance software. Skills and certifications tracking ensures the assignment of qualified personnel to specific maintenance tasks. Collaborative tools enhance coordination among teams, including shared schedules, messaging, and document access, fostering seamless communication and teamwork.

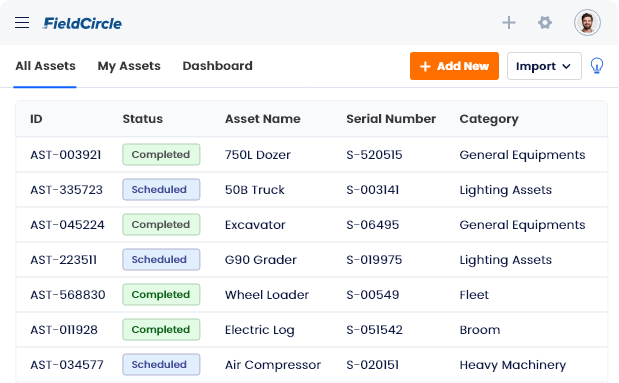

Assets and Equipment Management

Our software provides a centralized repository for all mining assets and equipment, including detailed histories, maintenance records, and performance metrics. Utilizing sensors and IoT integration enables real-time monitoring and condition-based maintenance alerts, ensuring proactive equipment management. Advanced analytics facilitate predictive maintenance, forecasting potential equipment failures before they occur, thereby minimizing downtime and maximizing operational efficiency.

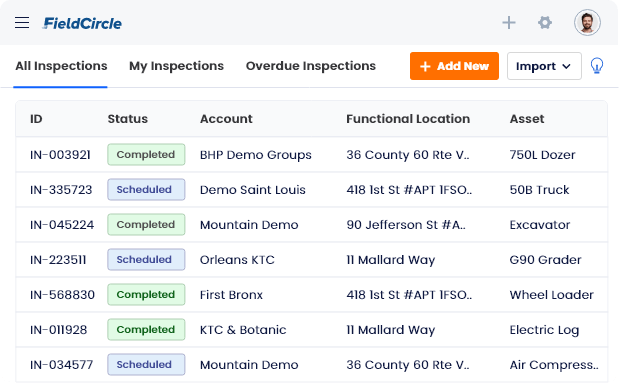

Preventive Maintenance, Inspection & Reports

Automated scheduling of preventive maintenance and inspections by our mining maintenance, based on equipment type, usage, and historical data, ensures optimal equipment performance and compliance with industry regulations. Checklist template management standardizes maintenance procedures and facilitates compliance. Detailed inspection reports and maintenance records support audit readiness and verification, ensuring regulatory compliance and operational excellence.

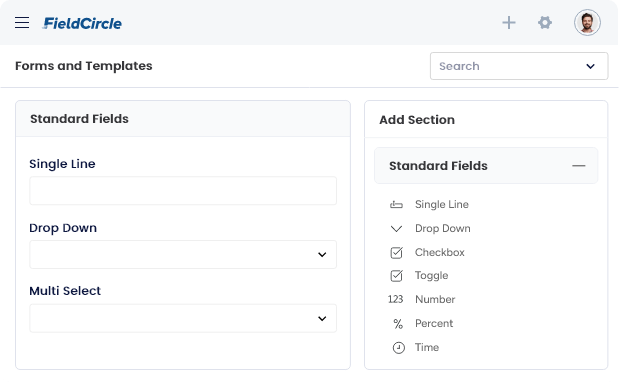

Checklist Template Management

Our mining maintenance software offers customizable checklist templates for consistent execution of preventive maintenance, inspections, and routine equipment maintenance across mining operations. Real-time updates and modifications to templates ensure alignment with evolving industry standards and asset performance insights. Embedded mandatory checks and measures within checklist templates facilitate compliance with mining and natural resources regulations, enhancing operational safety and efficiency.

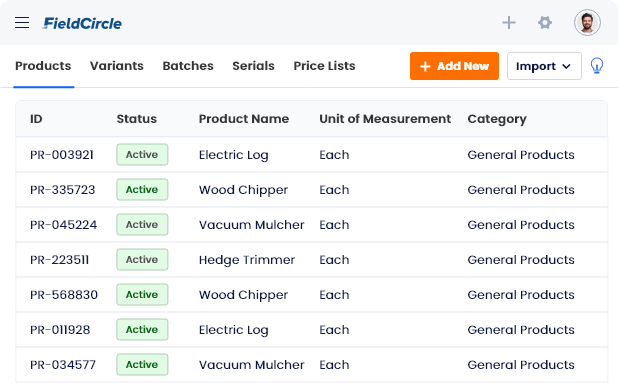

Inventory & Supplies Management

Centralized tracking of inventory levels, including spare parts and essential supplies, by our mining maintenance software ensures effective maintenance support. Automated alerts and predictive forecasting prevent stockouts, optimizing the supply chain and reducing maintenance delays. Robust vendor management features streamline the replenishment process, ensuring cost-effective procurement of high-quality materials, and minimizing operational disruptions.

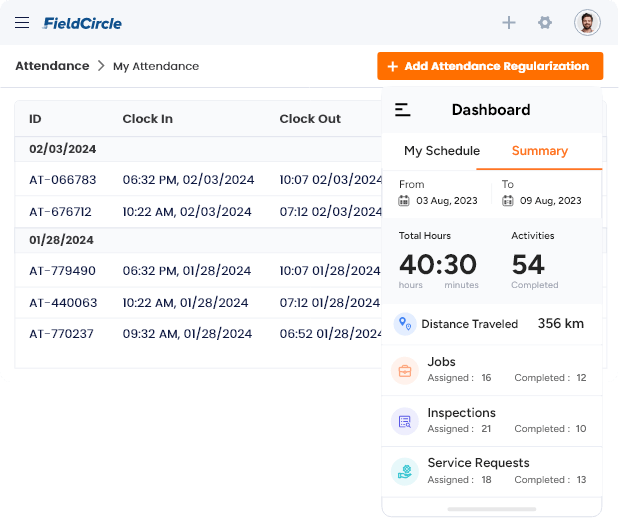

Time-Tracking & Timecards

Automated time-tracking feature of our mining maintenance software accurately captures technician and crew time spent on maintenance tasks, inspections, and cleanings. Mobile accessibility enables real-time timecard submissions, reducing administrative overhead and improving payroll accuracy. Labor data analysis by our software optimizes workforce deployment and identifies opportunities for increased productivity within mining maintenance operations.

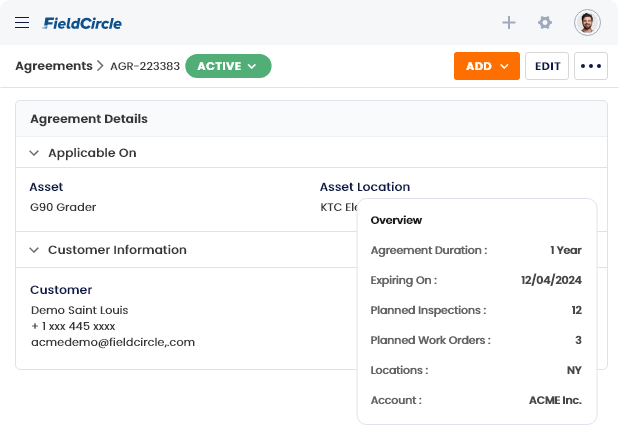

Contract & SLA Management

Centralized management of contracts and service level agreements (SLAs) ensures clear expectations and compliance. Automated tracking of SLA performance metrics alerts managers to potential issues, safeguarding client satisfaction and contractual obligations. Easy access to contract details and terms enhances negotiation capabilities and supports effective vendor management.

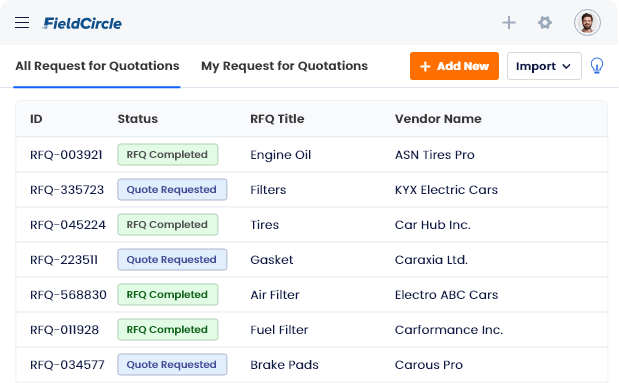

PO, RFQ, and Vendor Management

Our software streamlines procurement processes with integrated management of purchase orders (POs) and requests for quotation (RFQs), enhancing efficiency in vendor selection. Our mining maintenance software’s centralized vendor information database informs procurement decisions and negotiations, while automated workflows reduce cycle times and improve procurement efficiency.

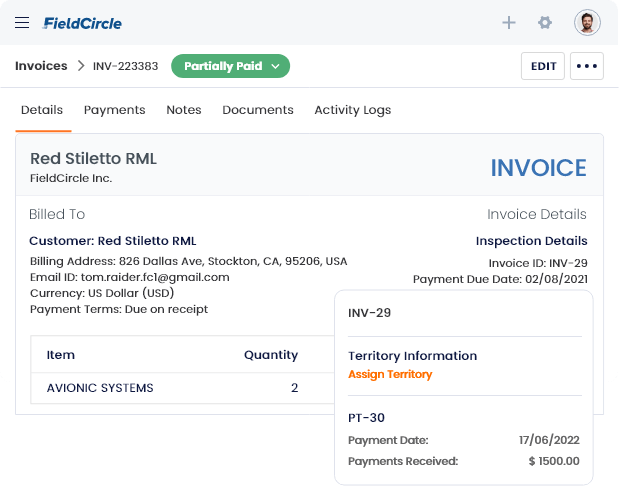

Invoice and Expense Management

Automated invoice processing and expense tracking feature of our mining maintenance software matches invoices to POs and service entries, reducing errors and improving financial oversight. Real-time management of maintenance-related expenses provides insights into cost control and budgeting for mining operations. Robust reporting tools analyze expense trends, identify cost-saving opportunities, and improve budget forecasting accuracy.

On-the-Go Management with Mobile Accessibility

Our mining maintenance software provides technicians and managers with mobile access, enabling real-time data capture, access to maintenance schedules, and work order management from any location. Mobile devices facilitate on-site asset inspections, inventory updates, and team communication, enhancing responsiveness and operational efficiency. Secure, mobile-enabled access to contracts, documents, and maintenance records ensures compliance and audit readiness, even in remote mining locations.

Businesses Like Yours Are Seeing These Results with FieldCircle’s Mining Maintenance Software

Why Businesses Pick FieldCircle Over Other Mining Maintenance Software

Integrations That Help You Get Most of Our Mining Maintenance Software

Companies Like Yours Are Seeing These Results

With Our Mining Maintenance Software

FieldCircle has provided a positive experience by significantly improving our service and maintenance operations through its robust features and reliable performance.

FieldCircle has been transformative for our ops. We were already using technologies but FC has replaced most due to its comprehensiveness and awesome support team.

Success Stories Led by Our Mining Maintenance Software

Discover the remarkable impact of FieldCircle as our trusted clients share their success

stories and

client feedback on how

they have transformed their service operations.

Cushman & Wakefield

Cushman & Wakefield, a global powerhouse in the commercial real estate services sector, enhances customer satisfaction, improves operational profitability, and achieves better vendor collaboration with FieldCircle.

Read the Story

TSI Power

A leading US-based manufacturer, TSI Power Corporation, USA improves resource utilization, enhances productivity with FieldCircle implementation.

Read the Story

Yourspace

YourSpace partners with FieldCircle to achieve service operations excellence leading to higher profitability and customer experience.

Read the Story

Nicco Engineering

Speciality maintenance service provider achieves more agile, transparent, and resilient service operations with FieldCircle.

Read the Story

Book a Personalized Demo

Learn how your business can use FieldCircle’s Mining Maintenance Software to achieve more efficient,

transparent, and profitable service operations.

By submitting your details, you agree that we may contact you by call, email, and SMS and that you have read our terms of use and privacy policy.

Frequently Asked Questions (FAQs)

Quick answer to questions you may have.

What is Mining Maintenance Software?

Mining Maintenance Software is a specialized solution designed to streamline and optimize maintenance operations in the mining industry. It helps mining companies manage their equipment, assets, and facilities more efficiently by automating maintenance processes, scheduling preventive maintenance tasks, tracking equipment performance, and ensuring compliance with safety regulations. This software aims to minimize downtime, extend equipment lifespan, improve operational efficiency, and enhance safety in mining operations.

How Much Does Mining Maintenance Software Cost?

The cost of Mining Maintenance Software can vary depending on factors such as the features and functionality offered, the size and complexity of the mining operation, and the vendor pricing model (e.g., subscription-based pricing or one-time licensing fee). Typically, pricing is tailored to the specific needs of each organization, with factors such as the number of users, level of customization required, and additional services influencing the overall cost. It’s best to contact the software provider directly for a personalized quote.

Is Integration Available in FC’s Mining Maintenance Software?

Yes, integration is available in FieldCircle’s Mining Maintenance Software. FieldCircle offers seamless integration with various systems and technologies, such as IoT sensors and devices, mapping software, supply chain management systems, predictive analytics and maintenance systems, and document management systems. These integrations enhance the software’s functionality by providing real-time data insights, optimizing maintenance operations, streamlining procurement processes, ensuring regulatory compliance, and maximizing operational efficiency in the mining sector.

Do Addons Cost Extra Dollars?

The availability and cost of addons for FieldCircle’s Mining Maintenance Software may vary depending on the specific addon and vendor pricing policies. Some add-ons may be included in the base software package, while others may incur additional costs. It’s advisable to consult with the software provider to inquire about available add-ons, their functionalities, and any associated costs. Additionally, the need for add-ons may vary depending on the specific requirements and preferences of each organization.