How to Calculate the ROI of CMMS System?

How to calculate the costs and ROI of CMMS? Is the computerized maintenance management software worth the buy? These are the questions that have been asked since the popularity of using CMMS software. For most maintenance managers, the value of CMMS system pricing seems obvious. The CMMS program is designed to maintain information about the organization’s maintenance process, which supports the maintenance managers to do their work effectively and effortlessly.

The users of the CMMS system can save tremendous amounts of money and time for the organization. Calculating ROI for any CMMS requires many pieces of information, but that is not easy to obtain. There are several factors to take into consideration when evaluating the cost and ROI of a CMMS.

CMMS ROI calculation formula

The Return On Investment (ROI) can be calculated by dividing the gains brought by the maintenance management by the cost of maintenance.

The ROI of CMMS can be calculated using the formula,

CMMS ROI = (CMMS Value – CMMS Costs) / CMMS Costs

The CMMS values can be calculated by adding productivity gains, downtime savings, and spare parts inventory savings. And the CMMS costs can be calculated by adding the implemented costs, software costs, and other additional costs.

The simple guide to understanding the ROI of CMMS

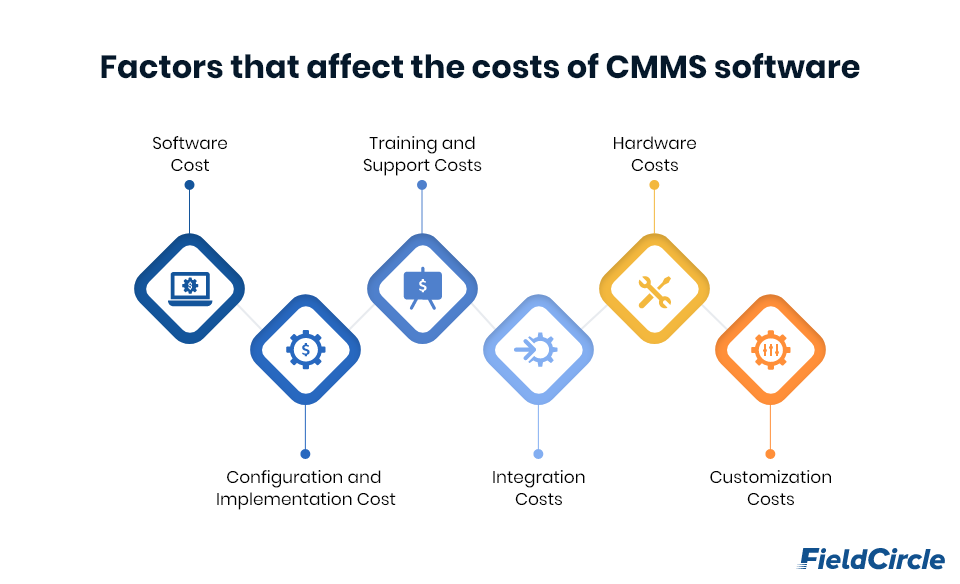

Let’s understand how CMMS software pricing is structured for both on-premise and cloud. These are the six factors that affect the costs of CMMS:

- CMMS software cost

- Configuration and implementation cost

- Training and support costs

- Integration costs

- Hardware costs, if needed

- Customization costs

The CMMS costs, cloud-based Vs on-premise

The CMMS vendor offers two solutions, Cloud-based CMMS and On-premise CMMS.

Cloud-based CMMS is delivered through a subscription model. The subscription is based on the number of users, who will use the software, and it is based on paying once a year. All the technicians who will use the CMMS program, including suppliers, are directly considered users. Usually, there will be a supervisor user who ensures the ability to convert reports into a work order and so on. So you want to calculate the subscription fee, based on only one question. How many people will use the CMMS system?

In addition to this fixed cost, there will be some additional costs which are usually not very high. But calculating these CMMS pricing is the most difficult part, it varies based on your wants and needs. Customization and integration are the most common extras that lead to deciding the final CMMS price.

Configuration and implementation cost

The cost of configuring and implementing CMMS includes the cost of both direct and indirect installation. The potential costs of implementation include system configuration, data entry, scheduled maintenance, etc. Most CMMS vendors offer standard implementation packages including all these services.

Training and support costs

The cost of training and support depends on the size and goals of your team. Most of the vendors add training hours with the purchase of the subscription fees, and additional training is charged by hours. This is the important part of buying the CMMS, successful implementation and training depend on how people are involved in using the software.

Integration costs

Integration with company systems is one of the essential elements to take maintenance to another level. Whether you want to connect the CMMS software with ERP, DBMS, or to the production schedulers, warehouse software, sensors, meters, and so on. This represents the way to achieve the best ROI using CMMS. These integrations will allow the users to collaborate with other departments and the information obtained from other systems to make the process more efficient.

The first step in determining the cost of integration is to understand what we want to connect to the CMMS. Talk to the supplier about the possibility of getting accurate information about the final costs.

Hardware costs

The purchase of the software represents some of the physical hardware costs associated with it. One of the important advantages of the CMMS is the ability to access it through a smartphone. This allows you to use the system directly through your own devices. For this the company needs to provide the corporate one, it will be good to calculate the cost in advance.

Customization costs

Customization is a smart move, but it is a decisive one. The CMMS providers often provide different environments based on the sector. You can make customizations that are different from your competitors. However, these customizations are divided into two categories, for the first one, the customization is simple, it denotes modifications to the interface. These customizations are generally done without adding any extra CMSM software costs unless they become too much.

Other CMMS customizations require greater effort by the provider. Some of them involve the development department, which will have to be paid for.

Calculate the Value of CMMS

What value does the CMMS offer? Calculating the ROI of CMMS depends on many factors, including the objectives we have set to achieve or the sector we operate in. This says that calculating the ROI of CMMS is not easy, until otherwise without knowing anything about the company. For this, we provide a list of areas that bring value to the business.

Downtime

Downtime represents the significant cost that the company loses every year. CMMS solution can help many companies to reduce this cost in many ways. For a manufacturing company, CMMS can help reduce the number of unexpected downtimes or help you plan scheduled maintenance rationally.

The CMMS can help you to,

- Understand the costs of a machine downtime

- Monitor the number of hours of downtime before and after implementation

- Analyze the failure types and evaluate their effects in terms of hours workers.

Eliminate inefficiencies

Eliminating inefficiencies can save you time and money. The main problem is to find them, this can be done with the help of CMMS. Once you have set the average working time to complete a specific task, the required working hours, and man costs, you can find answers to the following questions,

- Does less unexpected failure mean less staff?

- Is the preventive maintenance program sufficient to reduce the breakdown?

- Do automatic data entry, tracking options, and digital reports save time?

- Is the work assigned properly and done faster?

- Do you notice any improvement in communication that leads to shortening intervention time?

- Are the productive time, work quality, and total value of working hours increasing?

Analysis and efficiency

One of the key reasons to use CMMS is its ability to store and analyze the data to provide advanced reporting to make the actions easier. Some reports will help you to answer the following questions.

- Are we doing less scheduled maintenance? Optimal maintenance planning can cost 3 to 4 times less than reactive maintenance. This helps to reduce the excess costs and loss of efficiency.

- How much does the machine downtime cost?

- Has the average number of downtime of the machines dropped?

- Which assets need more maintenance, and what are the most expensive assets?

- What is the backlog ratio? Is it decreasing significantly?

Answering these questions will help you to find the CMMS ROI about the labor costs and time?

Inventory and spare parts warehouse

Management of spare parts and materials in the warehouse leads to a decrease in costs. You can measure this by calculating the amount you spent before and after implementing the costs. Here are some examples of how CMMS helps you better manage inventory.

You can save on the purchase of replacement parts through maintenance planning that allows you to predict a failure and reduce its costs. You can track the usage of spare parts and equipment in a single click, this avoids overstocking and running out when needed. This optimizes unnecessary costs by avoiding immobilized capital.

Asset efficiency and durability

The CMMS system ensures that the asset receives adequate maintenance to increase its durability and maintain more productivity standards. This will allow the company to save the equipment in the long run. This will have a major impact on the ROI of CMMS. This will allow you to,

- Increase the efficiency of the plants

- Extend the life cycle

- ROI calculation

Safety and sustainability

The CMMS provides high ROI in terms of safety and sustainability. Here are some the example,

- Best maintenance keep machines in good condition, reducing the utility costs

- Simplifies the management audit, compliance with safety procedures, deadline monitoring, and other procedures.

- Through these processes, the CMMS contributes not only to complying with required regulatory standards but also to creating a safer environment.

Integration with the business systems

With integration into the ERP systems, CMMS can share and collect data from different systems. This helps to generate even more ROI because even in maintenance, unity gives a major strength.

Finding the right balance for your business needs

The CMMS software market has evolved tremendously in recent years, both in terms of features, functions, and costs. Today, CMMS program price is available at lower rates than in the past, and even some open-source CMMS experiments.

Each software has different characteristics, capabilities, and different ROIs. Understanding the cost of CMMS brings value to the company. It helps with the careful analysis and definition of objectives that we want to achieve through the implementation of maintenance management software. Experts say that a feature-rich CMMS software can help the company to save between 5-15% of the maintenance budget. It is important to consider each element, check with different suppliers, and get the cost structure. The necessary effort and services behind the product can turn the extra gear into success.

Sneak peek of maintenance management ROI statistics

The maintenance management includes training, utilities, documentation, and so on.

- Each and every dollar you spend for preventive maintenance will save up to five dollars on other expenses.

- Almost 80% of employees waste an average of 30 minutes searching for important information for their work needs.

- The average time on searching a maintenance document is about 18 minutes.