What is Overall Equipment Effectiveness (OEE)?

Overall Equipment Effectiveness (OEE) is a metric that assesses the efficiency and performance of manufacturing equipment. It tells us how well production assets are utilized during the manufacturing process.

The metric combines three critical elements which are Availability, Performance, and Quality, into a single figure, and helps companies identify and address the root causes of inefficiency.

As an indicator of operational effectiveness, OEE highlights areas where machines, processes, or systems may be underperforming. It is one of those metrics with which maintenance and operations can reach the root cause of equipment inefficiencies, take corrective action, and improve equipment performance.

As we move ahead, we learn more about OEE, the process to calculate OEE, its benefits, its importance in maintenance, and how you can improve OEE with a maintenance management system.

How to Calculate Overall Equipment Effectiveness (OEE)

As said, overall equipment effectiveness (OEE) depends on three important factors – Availability, Performance and Quality. Each of these factors is expressed in percentage and dictate the OEE.

- Availability

Availability measures the percentage of time the equipment is operational during the planned production time. It takes into account any downtime that may occur, such as equipment failures, maintenance, or delays.

Availability is calculated as:

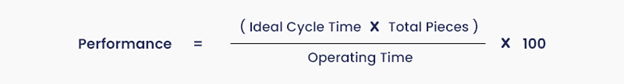

- Performance

Performance evaluates how fast the equipment runs relative to its designed maximum speed. It considers factors like reduced speed, minor stoppages, or operational inefficiencies that affect the equipment’s speed.

Here is how Performance is calculated:

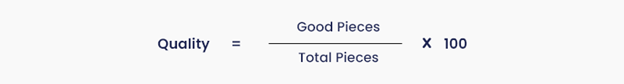

- Quality

Quality is calculated by determining the proportion of units produced that meet the desired standards. It takes into account any defective or reworked parts that do not meet quality standards.

The formula for quality is:

Once you calculate these three factors, you can multiply them together to determine the OEE score:

OEE = Availability × Performance × Quality

Let’s understand with an example. A machine is scheduled to operate for one 8-hour shift, which equals 480 minutes. We will walk through step-by-step calculation process to understand how understanding OEE calculation actually works:

- Availability

The machine was planned to run for 480 minutes. However, due to breakdowns and setup delays, it remained idle for 60 minutes. That means the actual time it was running is:

Actual run time = 480 – 60 = 420 minutes

Now, apply the formula:

Availability = Actual Run Time / Planned Production Time

Availability = 420 / 480 = 0.875 or 87.5%

- Performance

During the 420 minutes of active run time, the machine produced 380 units. It’s designed to produce 1 unit per minute, so ideally, it should have produced:

Ideal output = 420 × 1 = 420 units

Now, compare actual vs ideal:

Performance = Actual Output / Ideal Output

Performance = 380 / 420 = 0.904 or 90.4%

- Quality

Out of the 380 units produced, 20 were found to be defective and needed rework. The number of good units is:

Good units = 380 – 20 = 360 units

Now calculate:

Quality = Good Units / Total Units Produced

Quality = 360 / 380 = 0.947 or 94.7%

- Final OEE Calculation

OEE = Availability × Performance × Quality

OEE = 0.875 × 0.904 × 0.947 = 0.749 or 74.9%

OEE of 74.9% shows that the equipment is performing fairly well but is not running at peak efficiency. We interpret that downtime and the few defects present are affecting its overall effectiveness. A significant portion of the manufacturing time is losing to avoidable delays and performance drops.

What are the Benefits of using Overall Equipment Effectiveness (OEE)?

As mentioned earlier, OEE is an important metric and the following benefits of overall equipment effectiveness (OEE) shed better light on this fact.

Precise Identification of Production Bottlenecks

OEE helps pinpoint where delays or inefficiencies are occurring in the production process. By analyzing the Availability, Performance, and Quality rates, businesses can accurately identify bottlenecks, whether they’re related to machine downtime, speed losses, or quality issues, and carry out targeted interventions rather than broad assumptions.

Accurate Capacity Planning

OEE data enables more precise predictions of equipment capacity, and thus makes it easier to forecast production levels and schedule orders. Instead of relying on estimated capacity, OEE offers a more realistic measure of what can be achieved under current operational conditions, which can be leveraged for better demand alignment.

Optimization of Capital Expenditures

Understanding OEE helps determine whether new equipment is necessary or if existing machines can be improved. Rather than overinvesting in new assets, businesses can optimize their current assets through better equipment maintenance, setup procedures, and training.

Real-Time Escalation During Production Deviations

With OEE integrated into live dashboards, supervisors can instantly detect performance drops or quality dips as they happen. They can promptly take in-shift corrective actions and keep manufacturing operations on track without waiting for post-shift reports.

Data-Backed Evaluation of Operator and Shift Performance

You can use measuring OEE for objective comparisons across teams and shifts and thus identify training needs, reward high performance, and build consistency in operating procedures without relying on anecdotal feedback.

Dynamic Maintenance Prioritization

Declining OEE can signal emerging mechanical or process issues. Monitoring trends in availability or speed will assist operations teams to act based on actual usage patterns and performance indicators, paving the way for a more responsive mechanism and timely intervention.

Aids in Lean Manufacturing

Since lean methodology focuses on maximizing value while minimizing waste, OEE becomes a tangible way to quantify and act on inefficiencies. By continuously measuring and improving Availability, Performance, and Quality, teams work in line with lean objectives—achieving better output without increasing resources or time.

What is the Relevance of OEE in Maintenance?

The entire maintenance effort is centered around making equipment more effective and sustaining its efficiency. Mathematically, this is proven true through OEE. As a result OEE remains one of the important maintenance metrics, because it:

Isolates maintenance-related losses

By separating downtime, speed loss, and defects, OEE shows which issues are maintenance-driven, instead of mixing them with production or planning delays.

Connects equipment behavior to maintenance actions

OEE links real-time machine output to its physical condition, making it easier to see how maintenance quality impacts operational consistency.

Shifts maintenance from a support role to a performance contributor

With OEE data, maintenance becomes part of production analysis, not just an external function fixing breakdowns in the background.

Identifies where asset care is lacking

When availability or performance steadily drops, it’s often a sign of overlooked maintenance routines, poor scheduling, or ineffective servicing.

Distinguishes technical faults from non-maintenance problems

OEE helps maintenance focus on failures within their control, instead of chasing issues rooted in staffing, material flow, or operator errors.

Builds a measurable history of reliability trends

OEE trends show how well maintenance sustains equipment condition over time, providing early warnings before reliability fully breaks down.

What is a Good OEE Score?

The definition of OEE being a good OEE score will differ from business to business and industry to industry. However, general benchmarks are:

- 85% or higher (World-Class Performance): A top-tier OEE score, indicative of minimal downtime, optimal speed, and high-quality output.

- 70%–85% (Acceptable Performance): While production is generally running well, there’s still room to address inefficiencies and improve equipment performance.

- 50%–70% (Needs Improvement): At this level, the system is underperforming. Downtime, inefficiency, or poor quality is impacting overall performance, and immediate corrective action is needed.

- Below 50% (Urgent Issues): Equipment is heavily underutilized. Operational inefficiencies are severe, and require significant changes to prevent large-scale losses.

What are the Challenges in OEE Measurement?

OEE measurement presents several challenges that can complicate performance tracking. These are:

Susceptibility to Data Collection Errors

Inaccurate logging of machine downtime or defects can distort the OEE score. If maintenance or operational teams miss downtime periods or fail to classify defective products correctly, OEE metrics will fail to reflect the actual performance.

Complex Setups and Changeovers

Sometimes, machines may require long setup times before production starts. If this is not factored into OEE calculations, it leads to inflated Availability scores. Such operational conditions need precise configuration to yield accurate OEE data.

Fluctuating Production Cycles

In batch production or custom manufacturing, the ideal speed might vary based on the type of product being made. A performance score that doesn’t account for these variations will misrepresent how efficiently the equipment is actually running.

Lack of Standardized Quality Measures

Defective products that are not consistently tracked or recorded will distort the Quality component of OEE. The issue is more pronounced in production lines with varying quality standards or where multiple types of outputs are produced simultaneously.

Resistance to Change and Misalignment with Company Goals

In many environments, operational teams may not fully buy into OEE as a meaningful metric. When teams do not understand or align with OEE goals, they fail to provide accurate data or resist making necessary improvements and the whole process is undermined

How to Improve OEE with a Maintenance Software

The above discussion clarifies why you need OEE and why it matters to your maintenance process. As a next-step, you need a strong maintenance software that aids in OEE computation, monitoring, tracking, and optimization.

With its AI-enabled capabilities, FieldCircle is a great choice here. It effectively identifies chronic bottlenecks, correlates downtime patterns with asset history, and helps prioritize interventions that yield the highest OEE impact. So, it is not just fixing failures, but eliminating their root causes across shifts, lines, and plants.

At a broader level, our maintenance management software links asset performance data with production goals, and leadership can evaluate how maintenance decisions affect throughput, scrap rates, and cycle times, and overall manufacturing productivity. You thus shift OEE improvement from a technician’s task to a company-wide initiative which is driven by data, aligns with KPIs, and focuses on sustainable productivity.