The Definitive Guide to Outcome based Service Model

How a customer uses a product once it has been sold rarely used to be a concern for the manufacturer.

But, it is today.

Manufacturers today have shunned the “build and sell” centricity and are focused on consumption—how the product is being used.

Simply put, the value proposition of the product lies not in the hardware but in its ability to achieve its purpose—the outcome. The advancement in IoT technology, sensors, mobile computing, and wireless connectivity in the service and maintenance operations have made it possible for manufacturing companies to measure the “outcome” thus making it a business model and not just a performance KPI.

This model is referred to as outcome as service, facilitated by programs like CMMS and equipment maintenance software, allowing manufacturers to:

- Create a differentiating element to curb the effects of commoditization.

- Overcome the limitations of pure-product markets and explore the new opportunities in the service domain to increase revenue potential.

- Get deeper insight into customer consumption patterns, which could be used to optimize products and service delivery methods.

Customers on the other hand can identify the outcome and since the outcome is predetermined and the style of operations is transparent, their expectations are clear from the company, leading to a more trusted relationship and greater brand loyalty.

How Does Outcome as a Service Model Work

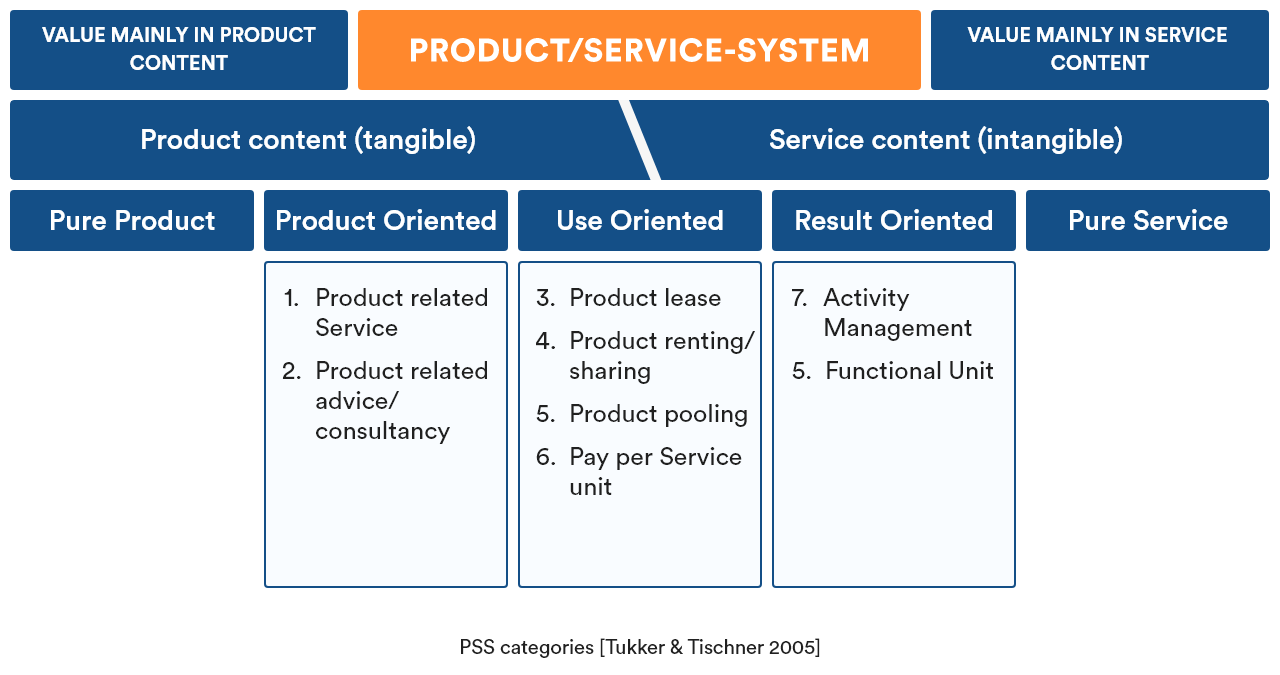

While services are inherent to manufacturing, in the traditional model, it is not included in the core offerings. In the new model, the outcome is what’s being sold; the manufacturers deliver it using a combination of products and services. The combination, known as product and service systems (PSS) could be structured in various ways to achieve an outcome. The most common PSS classifications are:

- Product-oriented PSS: The product-centricity remains intact in this model and services such as maintenance contracts, repair, and consultation revolve around the product to generate a renewable revenue stream.

- Use-oriented PSS: The ownership of product is transferred to the users under specific conditions in the form of lease, rentals, sharing, or pay-per output. The actual ownership remains unchanged and the owners are responsible for the management, maintenance, replacement, and control of the product.

- Result-oriented PSS: The product or service is not easily identifiable in the model. It has multiple stakeholders, however the product lifecycle management is the responsibility of producers, while the responsibility to achieve the outcome is on the service provider/outsourcing company.

These PSS categories indicate the servitization in manufacturing, wherein companies have blurred the line between products and services to disrupt the market.

Here are a few servitization examples of how leading organizations have used different categories of PSS models to generate new revenue streams and build brand loyalty.

Xerox: Pay-per-Copy

The earliest use of outcome as a service model traces back to 1959 when Xerox launched the model 914, the first plain paper photocopy machine. The machine produced an average of 2000 copies per day, at the time, when the daily average of other copier machines were 10-12 pages.

Apparently, Xerox 914 was expensive as it was built after considerable research and development and with a significant budget. In order to make the machine affordable, Xerox launched the pay-per-copy plan under which it offered the machine on lease, and charged the users for per-copy only in the excess of 2000 copies a month.

Within three years of the launch, by 1962, Xerox’s commercial copying business soared from $40 million to $400 million.

Bristol Siddeley/Rolls-Royce: Power by the Hour

In 1960, when in a first of its kind in the aviation industry, Bristol Siddeley, a British aero engine manufacturer, introduced the “Power By The Hour” service solution for their Viper engines.

The solution aimed at providing engine and accessory replacement services on a fixed-cost-per-flying-hour basis. So instead of purchasing the engine, operators had to pay for the power it provides, which relieved them from the burden of the capital cost of the engine and accessories.

In 1966, Bristol Siddeley was purchased by Rolls-Royce Limited. Almost 3 decades later, in 2000, Rolls-Royce Limited launched a Total Care Program under which it began selling “uptime,” ensuring that the engine is always up and running, serviced whenever needed.

From 2000 to 2018, since the adoption of the outcome as a service model, Roll-Royce’s market share of jet engines jumped from 14 percent to 35%. Also, at the start, only 10 percent of the engines were covered under the program, but by 2018, it covered 90 percent of engines, which is set to grow further.

Michelin Corp: Tire-as-a-Service

Michelin Corporation, one of the three largest tire manufacturers in the world, started a new division, Michelin Solution, to design, develop, and market services for commercial vehicles, mainly trucks.

The division launched EFFIFUEL to recommend and provide training in eco-driving techniques and optimize tire management systems. Its ecosystem is based on IoT technology to collect, process, and analyse data related to fuel consumption, tire pressure, temperature, speed, and location.

Michelin experts use the analysis reports to provide fuel-efficiency services risk free to truckers. Truckers would pay only if the predefined targets of savings are met.

The company helped truck operators reduce the fuel consumption by 2.5 litres per 100km, representing an annual saving of €3,200, including reduction of 8 tonnes in CO2 emissions, fulfilling their promises of enabling eco-driving.

Honeywell: Outcome based service for connected buildings

Honeywell has been actively working in the domain of connected building in Australia for 25 years. The company manages numerous building performance projects following the outcome as a service model, based on connected technology, condition-based monitoring, and smart algorithms.

One of its projects include providing facilities management services that focuses on air side systems and occupant comfort at a commercial office tower in Melbourne, Australia. In order to collect validated proof of the benefits of the outcome based service model, Honeywell ran a trial to compare the output of the outcome based model with the traditional model. Following were the results:

| Traditional approach-static tasking | New approach-dynamic tasking |

|---|---|

8 problems this year:

|

8 problems this year:

|

Source: Honeywell outcome based service case study

- Identified a number of faulty sensors ahead of schedule

- Tracked assets that were left in manual mode

- Found the critical causes of increased energy consumption and optimization opportunities to reduce energy consumption

These are by no means only successful companies in the servitization landscape, but certainly they are pioneers in using outcome as a service model to disrupt the market.

The road ahead is quite clear for the new entrants, however, finding a unique route using the model as a tool is key to success instead of creating a replica of existing approaches.

Enabling Outcome as a Service Model

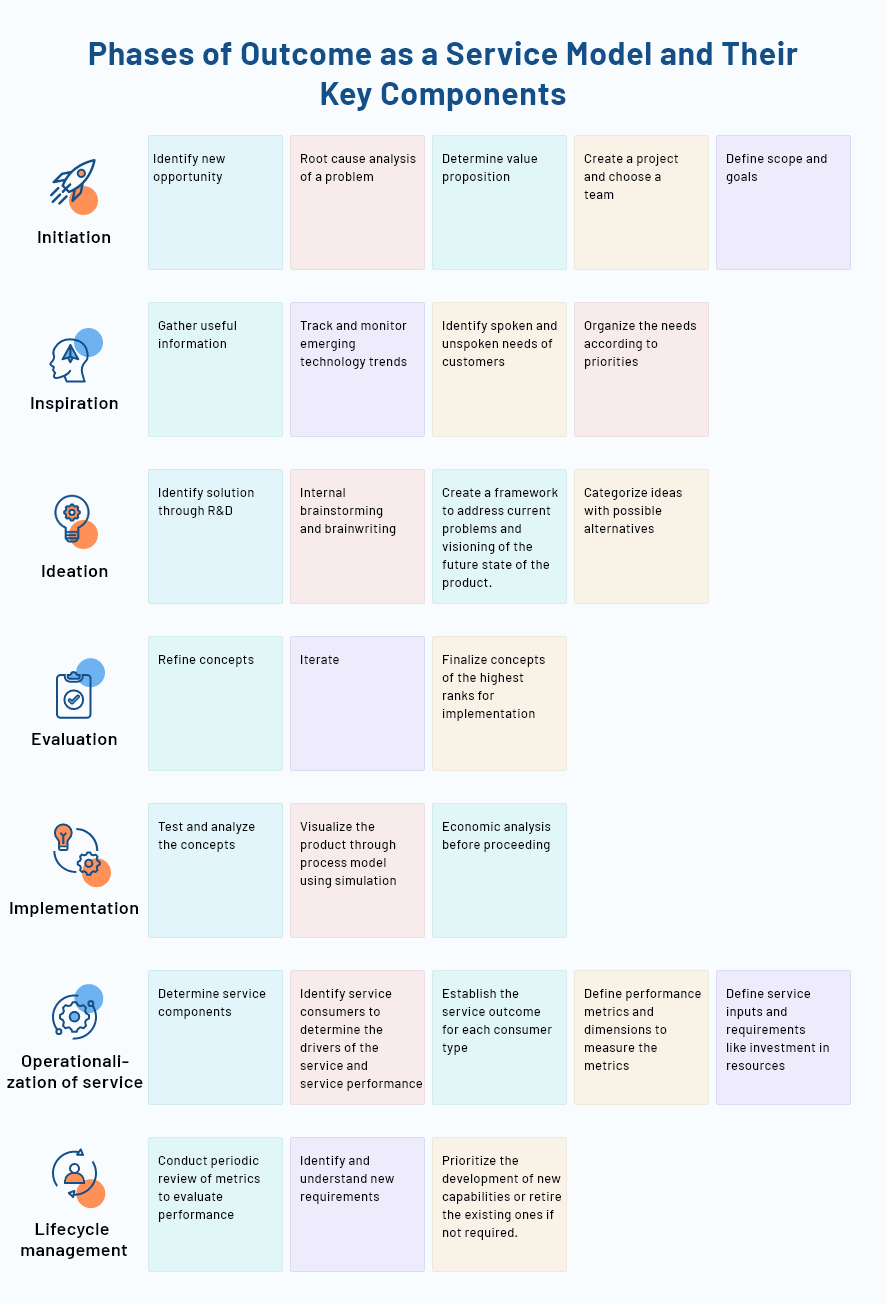

Enabling the outcome as a service model is complex and the level of complexity grows with the involvement of third parties, use of advanced tools, and the information required to make the service operational. Usually, there are multiple collaborative components at each phase of the model, as it has traits of both service and product, which makes the implementation a complicated process.

Let us take a look at the phases of the outcome as a service model and their key components.

Reference: Blekinge Institute of Technology, Karlskrona, Sweden 2017

One of the key challenges to enabling the outcome as a service model is to manage partnerships and fix the accountability of every stakeholder, especially in complex PSS categories. As there are multiple products, vendors, contractors, and outcomes involved, accurately determining the role, the value they bring, and the accountability associated with the role is a major success-driving factor.

Going Forward

The outcome as a service model opens up a new possibility to disrupt the market, for you and for your competitors alike. Who will disrupt the market depends on whose strategy has a better competitive edge.

FieldCircle is into transforming how global enterprises manage their field service operations. Our comprehensive and easy-to-use software suite with field service app, field service management software etc. help enterprises leverage the power of cloud, enterprise mobility, IoT, and data analysis to boost the performance of your service operations.